As technology improves and the need for efficiency in the supply chain increases, warehouse automation is becoming more commonplace. The task of bringing goods in and out of a storage area is both simple and crucial in terms of the overall process.

Conveyor belts have been in warehouses for decades already, whereby a human worker will pick an item or order from its location and then place it on the conveyor belt to be automatically carried to the despatch area. Companies such as Shop Direct use a similar system for incoming consignments too, with boxes going through a scanner en route to check size and weight.

However, companies such as Amazon are investing hugely in technology that uses robots to locate and pick items. Items are already transported around their fulfilment centres by machine, but the picking is still a manual process. The giant ecommerce retailer is already implementing aerial drones which replace the conventional ‘last mile’ solution of using couriers. Does this mean that there will be fewer people employed in a warehouse environment? Undoubtedly.

At present, fairly complicated tasks such as packing an item into a box and sealing it, are best done by humans. Robots traditionally do not have the dexterity and decision making skills that it takes to handle irregularly-shaped items. If the task was to move a square box from one location to another, a machine could be programmed to do this. However, without a human eye, human hands and a learned contextual understanding, there are still several tasks that cannot be fully automated in the supply chain environment.

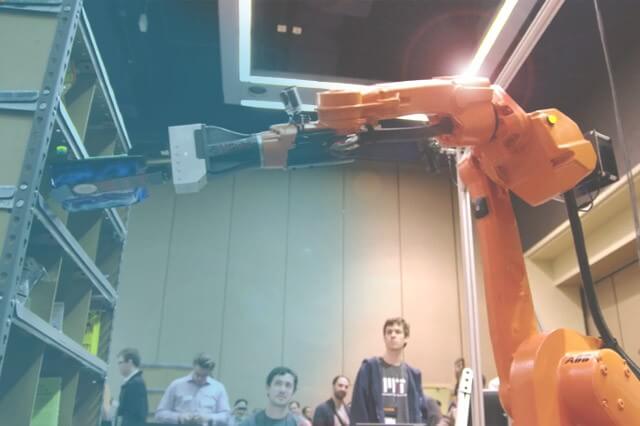

Amazon recently came up with a scheme to encourage innovation and basically help come up with the most efficient warehouse automation method. The Amazon Picking Challenge began in 2015 and the 2016 edition saw more robotics engineers compete to create an automated alternative to human warehouse pickers.

The popular perception of warehouse automation is that the subsequent redundancy of human roles will lead to an increase in unemployment. However, it could be argued that a more efficient, profit-making company would be in a better position to fund research and expansion. If the technology is there, industries will use it.

For now, there is still a huge amount that unskilled workers can add to the logistics industry. The large companies may be researching robotics, but there’s life in humans yet.